Apple CEO Tim Cook’s announcement that the company would do some Mac assembly in the U.S. brought on a flurry of publicity vastly disproportionate to the importance of the development. It’s good that manufacturers see opportunities for U.S. operations for a variety of reasons, but a big surge of employment isn’t one of them. Dan Luria, a labor economists with the Michigan Manufacturing Technology Center was quoted by Bloomberg as saying that the Apple operation is likely to add only 200 jobs.

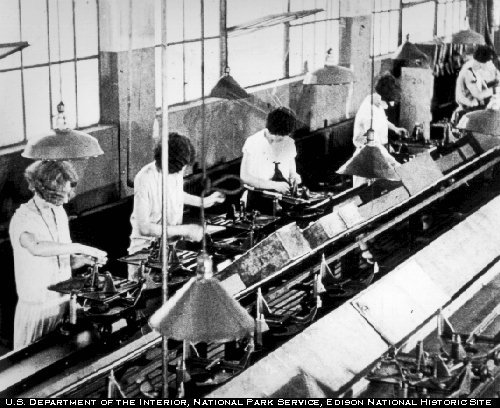

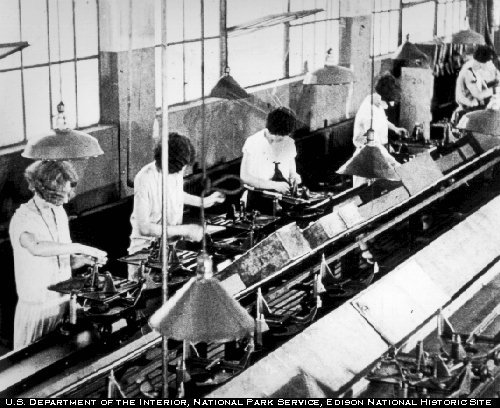

That’s not surprising to anyone who has visited a modern manufacturing facility, or who has seen only pictures of crowded Chinese assembly lines. Most factory work these days, especially in high-tech operations, is done by machines, not people (this is how a manufacturing company like Intel achieved revenues of more than half a million dollars per employee last year.)

The change is most striking in electronics assembly. Circuit board manufacture used to require humans to mount components on boards and solder them in place. Today, components have shrunk to the point where it is difficult at best for humans to place them with sufficient accuracy and impossible to solder by hand. Instead, high-precision robots place the parts on boards, which are then soldered in a quick trip through an induction furnace. Many Chinese factories still use lots of people for final assembly jobs because labor has been cheaper than robots; this is changing fast as Chinese wage rates rise.

A narrowing wage differential is one reason manufacturing in the U.S. is becoming more attractive. Rising shipping costs is another. As Quentin Hardy wrote in the New York Times Bits blog:

“The labor cost on a notebook, which is about 4 to 5 percent of the retail price, is only slightly higher than the cost of shipping by air. Soon even that is likely to change because of the twin forces of lower manufacturing costs from automation and higher transportation costs from rising global activity.”

The good news is that while the jobs are fewer, they are much better than most old factory work. Machines have taken over the heavy, dirty, dangerous jobs. (During my one summer of factory work, I spend a couple of weeks on the shipping line, sealing boxes, and applying shipping labels and postage. Back then, this was all done with glued tape and labels and I ended each shift covered head to waist in glue. I would have paid the robot myself to escape.) The jobs that remain are more for technicians than operatives. They require higher skills and generally offer higher pay and certainly better working conditions.